Pedrali’s Green Corporate Carbon Footprint

06 Dec, 2022

The commitment of the 100% Italian company towards continuous improvement

Since 2018 Pedrali measures its Corporate Carbon Footprint, calculating the total amount of greenhouse gas emissions produced by the whole supply chain, and obtains the UNI EN ISO 14064-1:2019 certification. The assessment measured the total greenhouse gas (ghg) emissions produced, directly and indirectly, by the organisation’s business activities over a given time interval. Upon analysing the results of this assessment, Pedrali aims to reduce the CO₂ emitted into the environment.

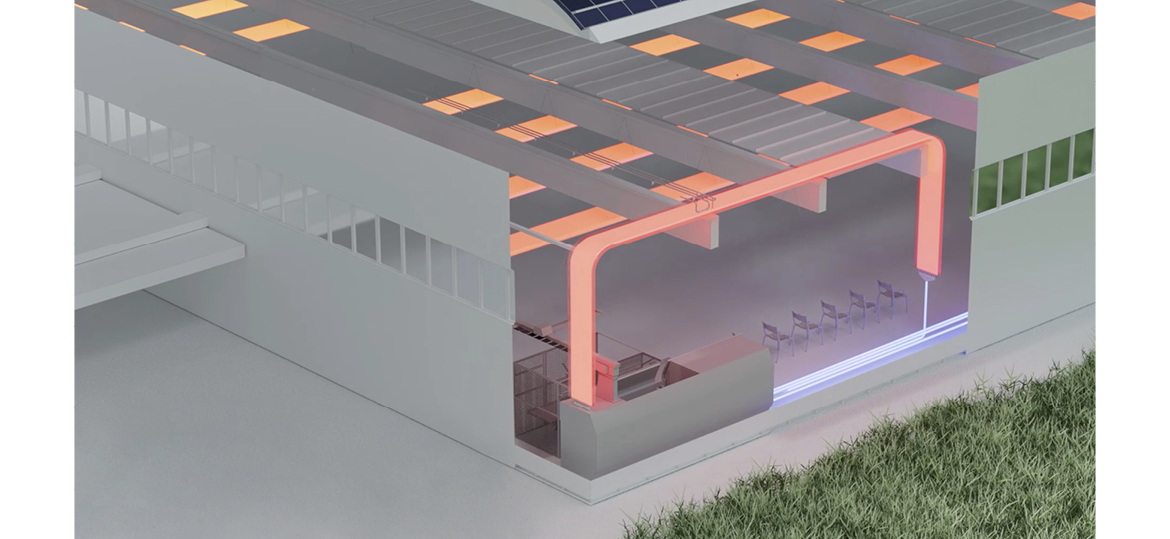

In order to do this, and to quantify and measure the results achieved, the company is implementing a series of improvements relating to each of the above sources. This will make it possible to record the positive swing expected in the coming years, and to set clearly identifiable goals. To mention a few concrete examples, Pedrali installed more than 6.000 sqm of photovoltaic panels on its plants, producing a total amount of 1,2 mw of energy, able to cover the company’s energy needs. Cooling towers that lower the water temperature of the moulds allow water recycling and less energy consumption. In winter the hot water produced in plastic materials moulding processes heats the other departments. The company also converted the lighting system of all indoor and outdoor plants to led. Pedrali produces "just in time", "what you need when you need it", and through the lean production it reduces raw material waste.

In order to do this, and to quantify and measure the results achieved, the company is implementing a series of improvements relating to each of the above sources. This will make it possible to record the positive swing expected in the coming years, and to set clearly identifiable goals. To mention a few concrete examples, Pedrali installed more than 6.000 sqm of photovoltaic panels on its plants, producing a total amount of 1,2 mw of energy, able to cover the company’s energy needs. Cooling towers that lower the water temperature of the moulds allow water recycling and less energy consumption. In winter the hot water produced in plastic materials moulding processes heats the other departments. The company also converted the lighting system of all indoor and outdoor plants to led. Pedrali produces "just in time", "what you need when you need it", and through the lean production it reduces raw material waste.